What is Laser Structuring?

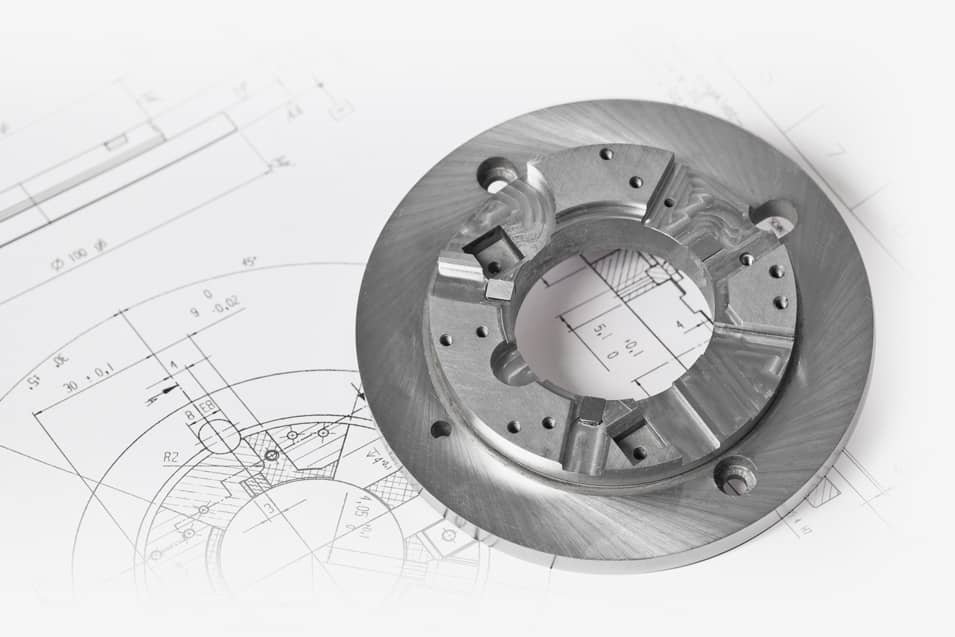

Laser structuring involves the laser precisely forming regular patterns in a material layer or substrate. This process modifies specific technical characteristics and creates new functionalities.

For example, by introducing microscopic peaks and valleys on the surface of a material, laser structuring can enhance surface properties like improved adhesive bonds or altered reflective qualities.

The process uses short, intense laser pulses to generate high energy densities, primarily causing the material to sublimate or evaporate. Each pulse creates a small indentation, minimizing the formation of molten material.

What is Laser Structuring Used For?

Laser structuring is utilized for a variety of purposes, ranging from aesthetic applications in the watch industry, such as creating matte effects or intricate designs on dials, to technical applications.

These include activating surfaces for improved adhesive bonding, reducing light reflection, or generating specific thermal properties.

Materials suitable for Laser Structuring

A wide range of materials, including metals, plastics, glass, and even composites, can be precisely treated with laser structuring without damaging their structure.

The versatility of laser technology allows for the creation of extremely precise and varied textures tailored to the specific needs of each project.

Laser Structuring vs. Laser Ablation

While both laser structuring and laser ablation are technically similar, they differ in their goals and outcomes. Laser ablation is used for removing material to create a smooth surface or specific patterns.

In contrast, laser structuring focuses on creating intricate textures on the surface.

In Which Markets Do We Succesfully Apply it?

Laser structuring has found applications in diverse markets, including the medical field, electronics, machine construction, and the watch industry.

The Advantages of Laser structuring

Laser structuring offers numerous benefits: it's environmentally friendly, requiring no additional blasting agents or chemicals; it achieves excellent precision for complex patterns and textures; it's a wear-free process that avoids contact with materials, reducing waste and increasing production efficiency.

Why Choose Laser Structuring at Lasertec

At Lasertec, we excel in the precision required for laser structuring. Our state-of-the-art equipment and skilled technicians ensure the utmost accuracy in each project. Whether enhancing adhesive bonds, creating aesthetic designs, or improving material properties, Lasertec delivers bespoke solutions for diverse needs.

Laser structuring provides the ability to transform and enhance materials, achieving everything from subtle aesthetic modifications to significant improvements in functional properties. Lasertec is dedicated to offering innovative solutions in laser structuring for various projects.

For more information about our laser structuring capabilities or any of our other services? Please contact us at

+31 180 644 744

or fill in the contact form.

Process combination

Through an intelligent combination of process and know-how, we exceed the limits of what’s possible

Competences

Thanks to our years of continuous development, we offer many possibilities within our company. The laser today represents a strong and reliable process that can be adapted to different applications. Most laser capabilities are accessible within the same process. Imagine: texturing a surface, engraving your logo, and cutting parts with a single laser.

-

LASER ABLATION

LASER ABLATION -

LASER WELDING

LASER WELDING -

MECHANICAL BENDING

MECHANICAL BENDING -

LASER STRUCTURING

LASER STRUCTURING -

LASER DRILLING

LASER DRILLING -

LASER CUTTING

LASER CUTTING

Numbers

Our success would not be achievable without a significant number of different laser

production units, years of experience and most importantly, a strong team.

More than

25

Laser production units

More than

37

People

More than

27

Years experience

Contact Us

We will get back to you as soon as possible.

Please try again later.

All Rights Reserved | Lasertec